Overview

Factory Production Management System or FPMS plays a crucial role in controlling, monitoring and making sure the effectiveness of remote system operation; provides users with flawless values through no-leftover process.

The main upsides of the system

- The system is stringently monitored for scheduled operation;

- Schedule maintenance;

- Wastes are eliminated during production:

+ Defects;

+ Overproduction;

+ Waiting;

+ Non Utilized Talent;

+ Transportation;

+ Inventories;

+ Motion/Movement;

+ Over Processes.

Production line costs the least, but optimised quality is met;

Clients are provided with finest service and values.

Factory Production Management System or FPMS

Analysis of the system

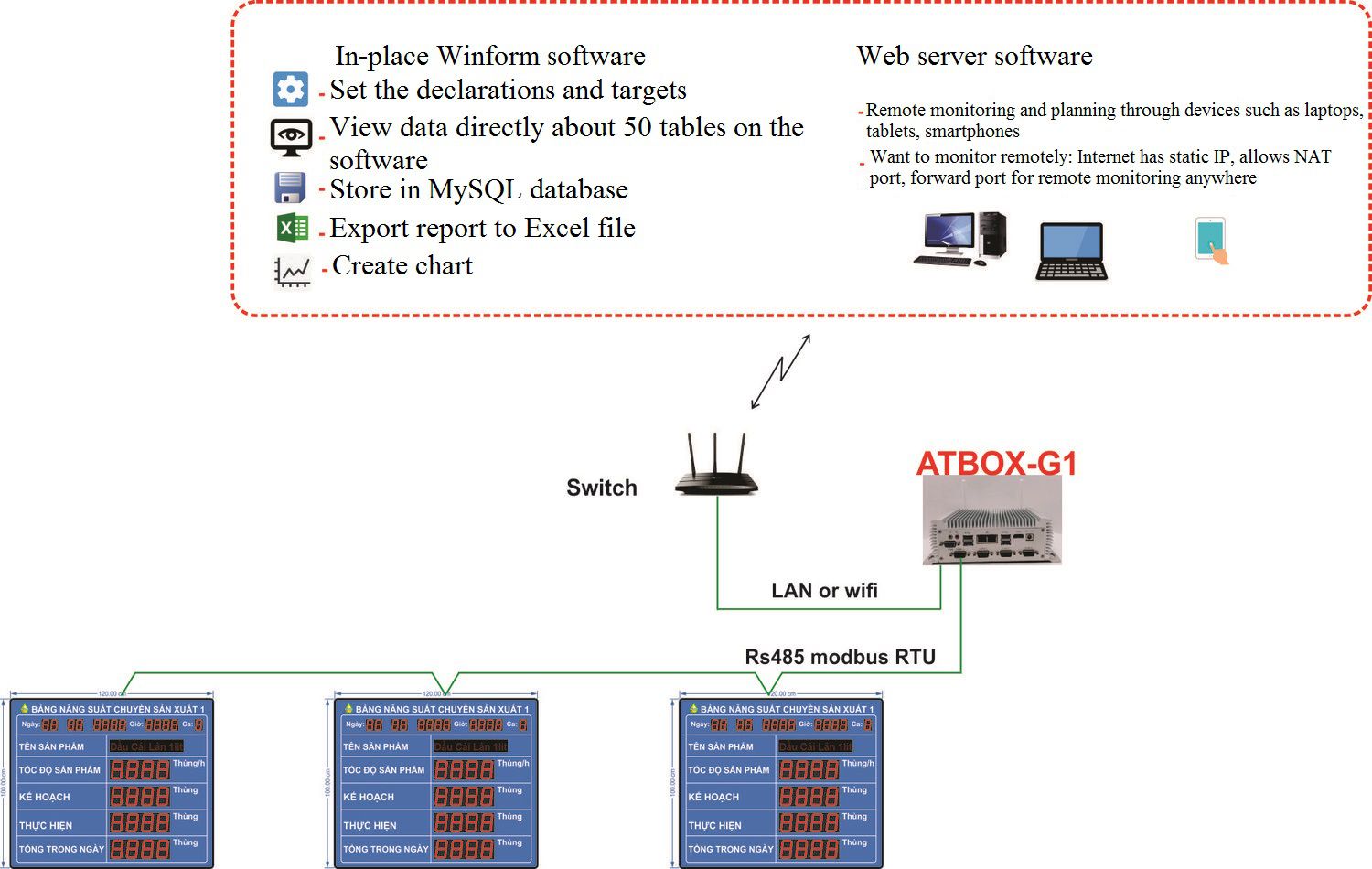

The FPMS can be deployed with the following components:

1 – The production operating room is equipped with SCADA, Andon, MES system.

All PCs with installed remote monitoring functions are connected to the system via Ethernet.

- SCADA PC collects data, monitor and control all instruments in the control room by connecting PLC, SMART IO,… via Ethernet.

- Andon PC:

+ Collecting data about machines’ operating status;

+ Andon status is directly displayed, reported and warned on Andon PC;

+ Initiating in-site alert or sending SMS alert via SMS modem.

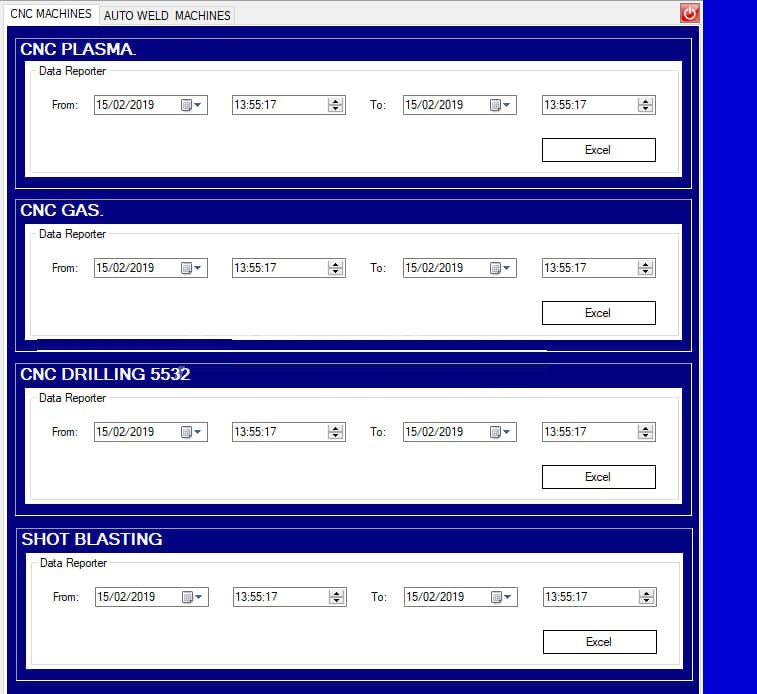

- Report PC:

+ Monitoring parameters on the system are displayed digitally or through chart;

+ Connecting and collecting actual date from instruments in the system: PLC, AT-DIO8, notifications and data about actuators (such as: sensors, push buttons, signal tower,…) are displayed via LED VDU;

+ Creating Excel reports;

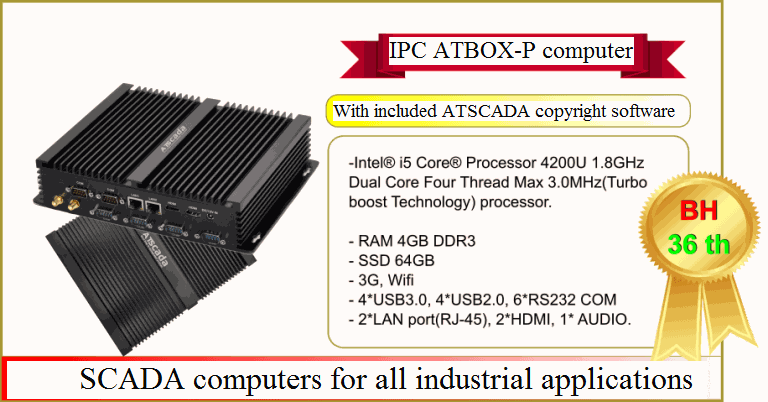

The ATSCADA software, integrated with FPMS, is “packaged” in ATBOX-P. This software, responsible for sending date to Cloud Server, allows all mobile devices to have access to the system.

2 – Easy-to-track management system

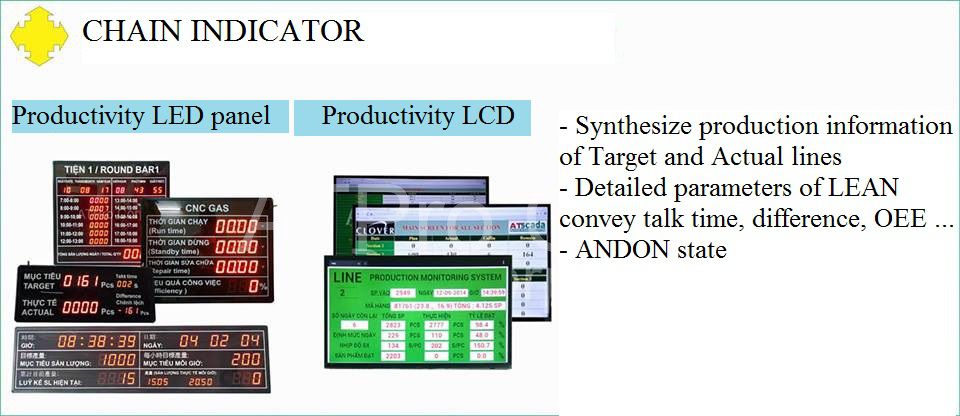

Vivid visualization displayed on the monitoring software via LCD, HMI includes: charts, production effectiveness measuring table, OEE parameters,…

Information about manufacturing progress, quality tracking, operating duration of machines, actual production, overall performance,… is displayed on the VDU. The VDU is also engineered with eye-catching graphic, deploys customizable LEDs.

References of the display can be found below.

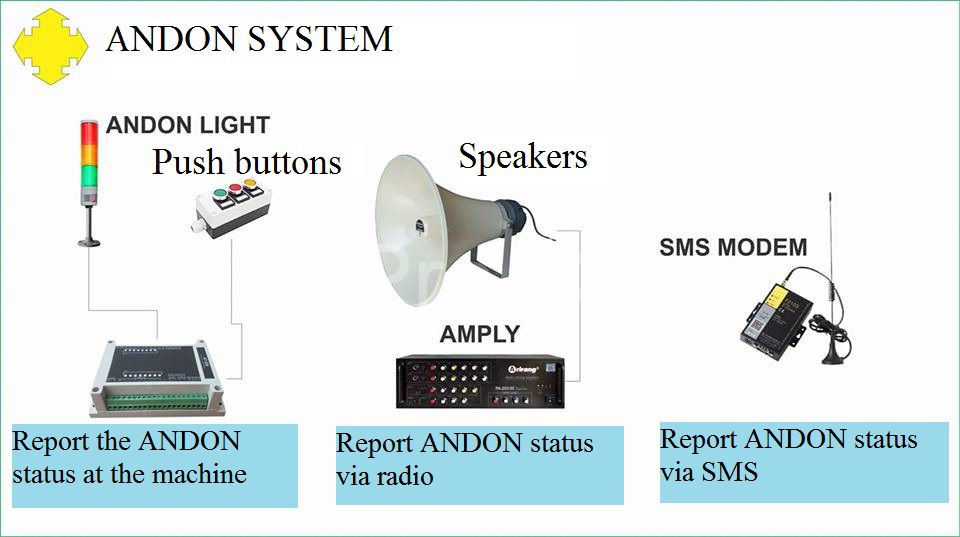

3 – Andon system

Colorful Andon signal tower provides users with effective supervision during manufacturing process and in-time troubleshooting.

For instance: Red indicates “deactivated”, Yellow indicates “require servicing”, Blue indicates “in used”.

Amply, Speakers and SMS modem

Audio system is used for notification about actual operating states of machines:

When the push button is triggered for servicing or re-fuelling requirement, notifications from the audio system will be sent to that particular site;

At the same time, when an error is reported, the system will send messages, alerting phone calls, emails to previously-set phone numbers and emails.

Andon system assists users in monitoring operating states of machines and thoroughly handling all damages during production that may affect the OEE factor (Overal Equipment Effectiveness).

4 – The CPU

Features:

- PLC, SMART IO are connected to machines. They are responsible for controlling, collecting data from machines in the system, and monitoring machines’ working efficiency.

- Devices that read Pulse signals, Analogs, ... and simultaneously control the siren on the spot or other devices to warn about machinery problems (equipment stops working, equipment fails, equipment, ...).

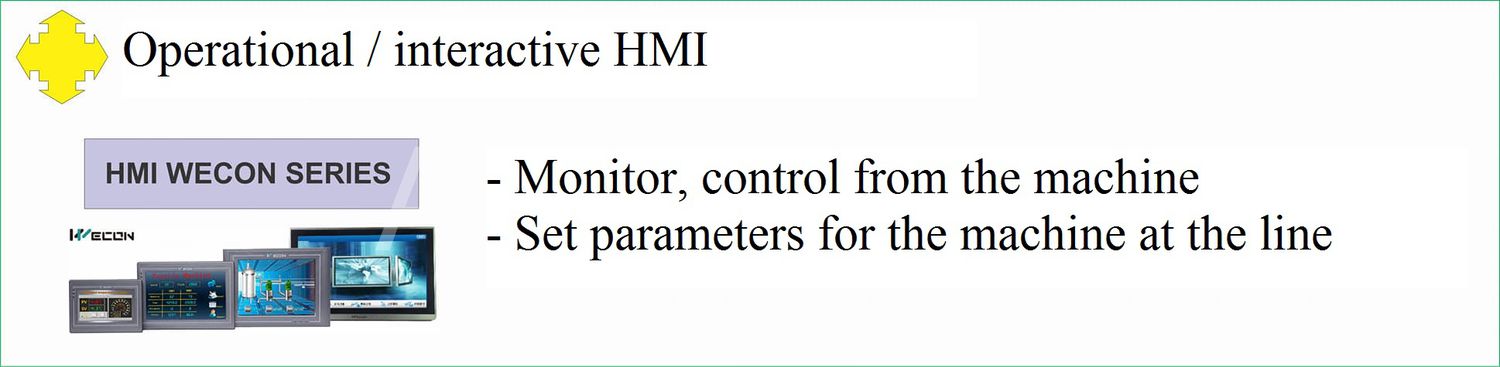

5 – Human-Machine Interface

HMI is deployed in the system to:

- Monitor, control and set necessary parameters for machines;

- Monitor the quantity, quality of products in set sites;

- Enable users to have direct operations with features displayed on HMI.