Overview

Measuring the solution level in silos, tanks, ... is a specific requirement in most production, operating lines at such factories as oil and gas, chemicals, thermoelectricity, water treatment. waste, ...

There is a wide variety of measurable liquids, with specialized sensors capable of measuring these values.

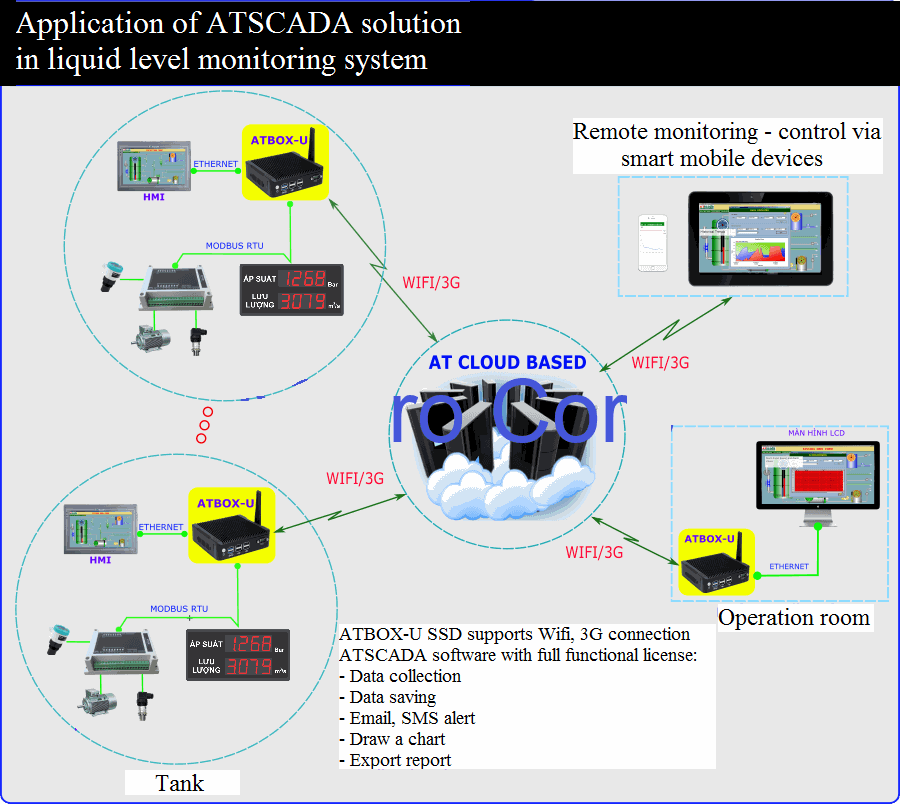

However, for centralized monitoring of all tanks in the plant, a complete SCADA system with data collection, control and storage is required.

This system will collect data from liquid level sensors at dispersed locations, transmit signals to the centralized management and control center of the whole system.

The main upside of SCADA application in measuring liquid level in tanks

- Distributed system, integrating management of multiple stations at various locations;

- Actual fuel level control (high level, low level) ensures automatic pump stimulation;

- Data storage for up to 10 years on Cloud Server;

- Integrated leak management to help detect fraud or unusual fluctuations;

- Alert the system immediately by SMS, Email;

Liquid level monitoring system solution

EMIN specializes in providing system integration solutions, SCADA solutions, applying all monitoring and control systems.

Solution for monitoring liquid level in tanks We propose to apply in the fields of oil and gas, water treatment, ...

SMART IO + ATBOX-U are located at the monitoring position of liquid tanks that collect measured data from the sensors, and transmit data to Cloud Server via Wifi / 3G connection.

When the Wifi / 3G signal is disconnected and restored, the ATBOX-U continues to transmit data to Cloud Server, ensuring stable connectivity for the system.

Equipment applied in the system

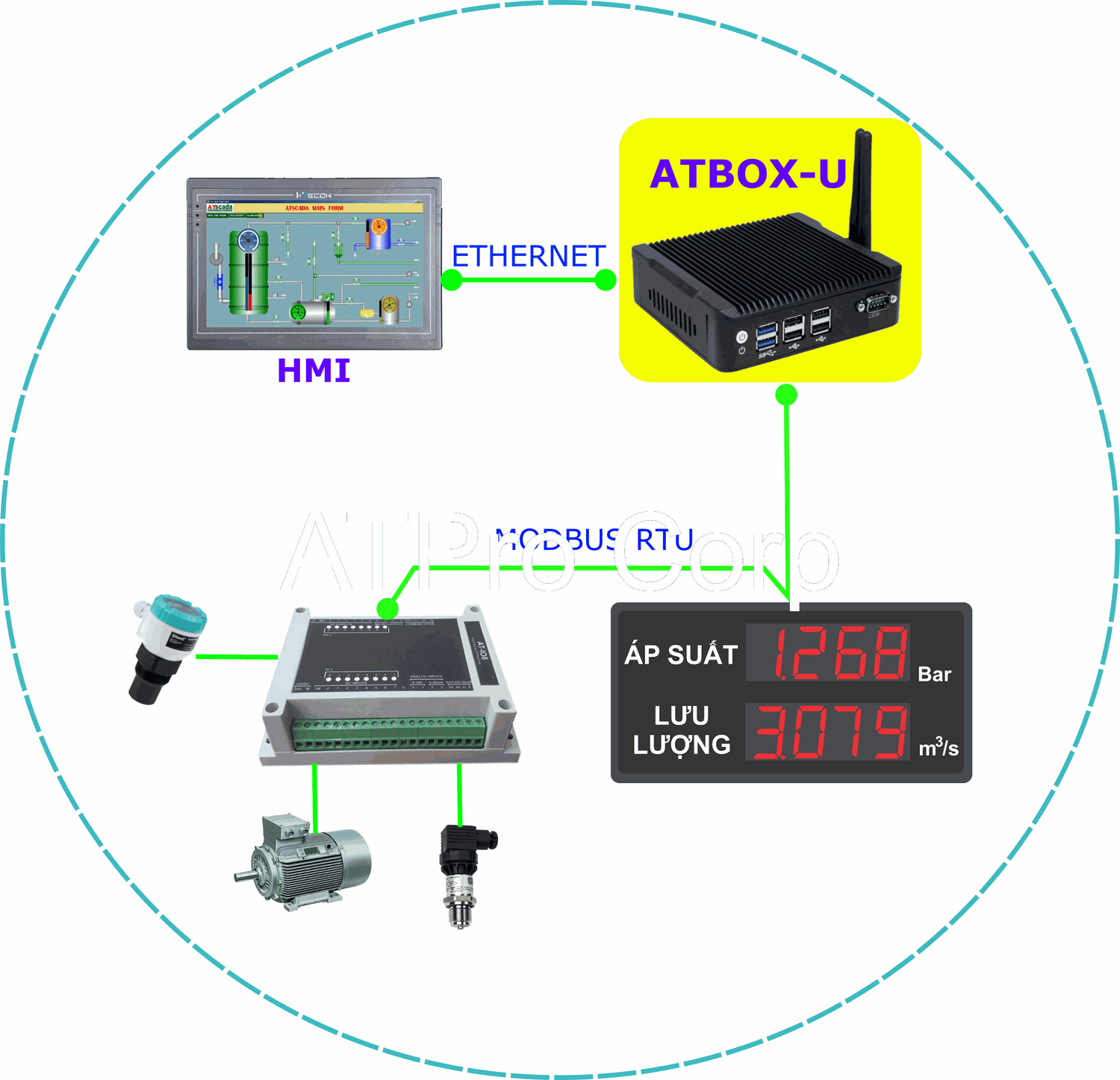

Industrial computer ATBOX-U

- Includes proprietary ATSCADA software for liquid level monitoring systems.

- AIL alloy frame design, compact, light weight, flexible for installation.

- Fanless computer, low power consumption, quiet operation - no noise.

Display port 1 * DP and 2 * HDMI, 2 * Gigabit Ethernet, 1 * RS232 COM, ...

Signal transmission plan: Wifi or 3G.

* SMART DI / DO AT-DIO8 expands 8DI / 8DO to connect the devices:

- Pressure sensors;

- Sensor measuring Analog signal 4-20mA or 0-10V;

- Relay click on/off Motor; ... other equipment needed for the system.

* Human - Machine Interface - HMI

- The HMI is used for monitoring - controlling the system to measure the liquid level in the tank at the electrical cabinets or mounted on the monitoring site of the tank.

- Connect to ATBOX via Ethernet (or RS485) port to transfer data stored on Cloud.

* Monitoring tables indicate parameters pressure - flow in place

- LED digital display board, can be placed indoors or outdoors (custom design);

- Design board with Modbus RTU input;

- Monitoring measured parameters from on-site sensors is easier and more convenient.

SCADA software monitors the system

On the Cloud Server of the solution level monitoring system, the web-based ATSCADA software collects data from the devices in the system and fully performs SCADA features:

- Real-time monitoring and data processing;

- Data storage of the system;

- View the operating status of the system in the form of numbers, graphs, ...;

- Make alerts via Email, SMS;

- Export reports to Excel files.